Interlining plays a crucial yet often overlooked role in the textile and apparel industries. While the outer fabric of a garment usually receives all the attention for its aesthetics, the choice of interlining can greatly influence its final performance, comfort, and fit. This comprehensive guide will delve into how interlining enhances fabric performance and affects the overall fit of garments, covering everything from the basics to advanced material technologies and design considerations.

Understanding Interlining: What It Is and Why It Matters

What Is Interlining? Interlining is an additional layer of material sewn or fused between the outer fabric and the inner lining of a garment. Its primary function is to add structure, durability, insulation, or properties like stiffness or flexibility to the garment. Interlining is frequently used in tailored garments like suits and coats and in accessories like collars, cuffs, waistbands, and hats.

Why Interlining Matters While interlining remains unseen, its impact is highly visible. It influences the garment’s drape, resistance to wear, and longevity. Choosing the appropriate interlining is critical because it provides additional qualities to the fabric, helping it hold up against repeated use, laundering, and environmental factors. The importance of interlining goes beyond aesthetics; it directly affects the functional performance of the fabric and, ultimately, the customer’s satisfaction.

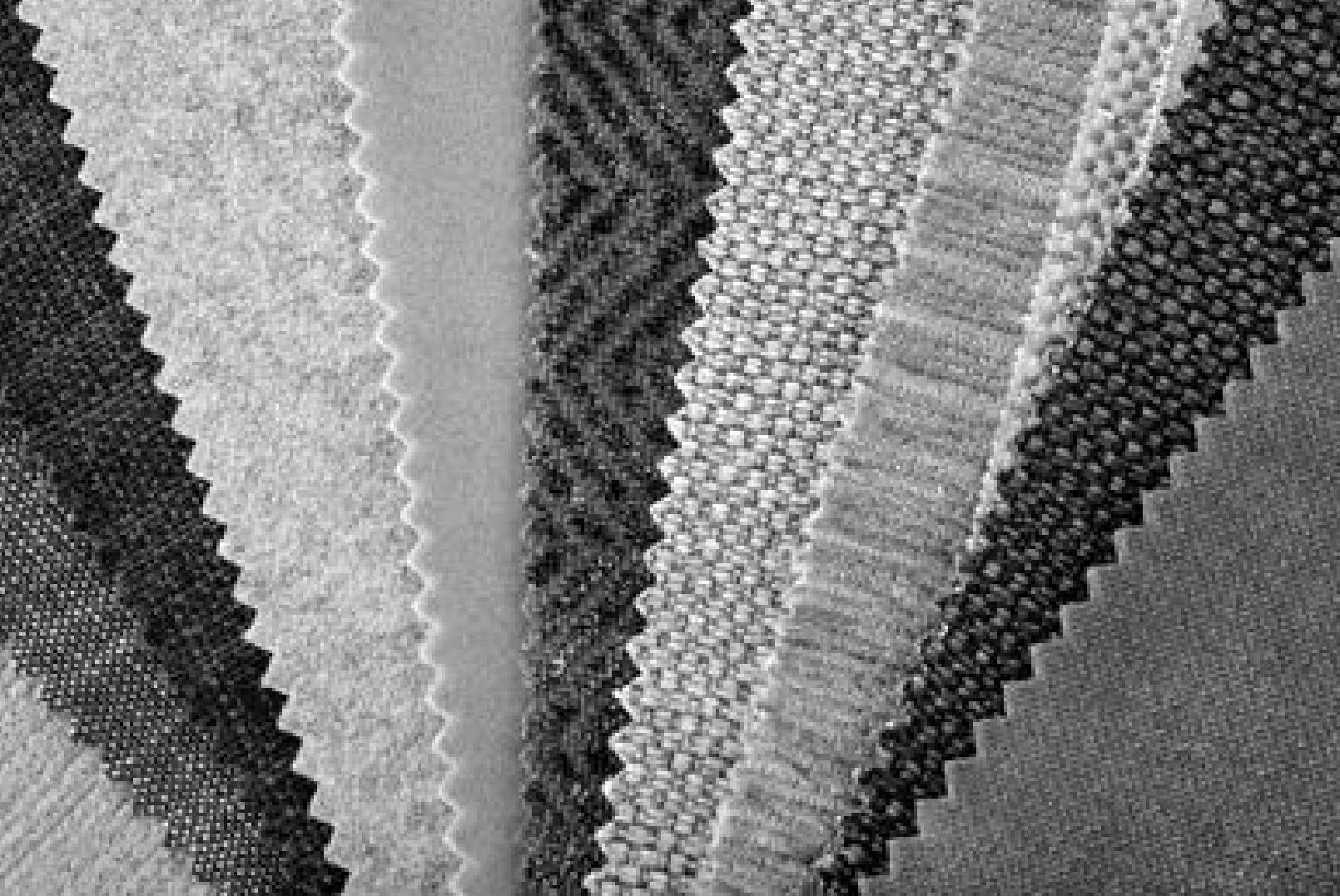

Types of Interlining and Their Characteristics

Different interlinings offer varied benefits, making it important to understand the options available and select the right type for the intended use.

Types of Interlining

- Fusible Interlining: Made with a thermoplastic adhesive on one side, fusible interlinings are bonded to the outer fabric through heat application. They are popular in modern garment production for their ease of use, faster application, and consistent adhesion.

- Sew-in Interlining: Attached through stitching rather than heat, sew-in interlinings are preferred when the garment requires a softer drape or when heat-sensitive fabrics are used.

- Knit Interlining: Made from stretchable knit materials, knit interlinings are often used in sportswear and garments that require flexibility, like dresses, blouses, and activewear. They add structure without restricting movement.

- Non-Woven Interlining: Created by bonding fibers rather than weaving or knitting, non-woven interlinings are versatile and used in applications where durability is more important than aesthetics, such as pocket linings or shoulder pads.

The Role of Interlining in Enhancing Fabric Performance

Interlining enhances several key performance characteristics of fabrics. Each type of interlining adds specific qualities, ultimately affecting the garment’s functional performance.

1) Durability and Resilience

Interlining reinforces the fabric and provides additional strength, helping garments withstand stress and maintain their shape over time. By adding an extra layer, interlining protects the garment from wear and tear, particularly in high-stress areas such as shoulders, cuffs, collars, and waistbands.

2) Insulation and Thermal Comfort

For winter apparel, interlinings often contain insulating fibers that improve heat retention, keeping the wearer warm while minimizing fabric bulk. Thermal interlinings add an insulating layer that traps body heat, making them essential for outerwear, jackets, and coats.

3) Moisture Management

Some interlining materials are designed to manage moisture by wicking it away from the body or providing breathability to prevent sweat buildup. This is particularly useful in sportswear and activewear, where moisture management is crucial for comfort.

4) Stain Resistance and Anti-Odor Properties

Certain interlinings are treated to resist stains or control odor, which is beneficial for apparel intended for frequent or long-term wear, such as uniforms or sportswear. These interlinings help keep garments fresh for longer and reduce the frequency of cleaning.

How Interlining Affects Garment Fit and Comfort

Interlining improves durability and resilience, but it also crucially shapes a garment’s fit and feel.

1) Support and Shape Retention

Interlining reinforces a garment’s structure, helping it retain its intended shape even after extended use. For instance, in tailored suits, interlining is used in lapels, collars, and cuffs to maintain the crisp, structured look that suits demand. With interlining, fabrics would sag, wrinkle, or lose shape over time, leading to a better fit.

2) Improved Drape and Smoothness

A garment’s drape is critical to achieving a polished appearance. Interlining adds weight to the fabric, allowing it to drape more elegantly and reducing the visibility of seams and wrinkles. This is particularly important for formal and professional wear, where a sleek, smooth look is desirable.

3) Flexibility and Ease of Movement

In garments requiring freedom of movement, such as sportswear or activewear, interlining must balance structure and flexibility. Knit or stretchable interlining provides the necessary support without compromising flexibility, allowing the garment to move with the wearer comfortably.

4) Comfort Against the Skin

Interlining enhances comfort by providing a layer between the outer fabric and the skin. This is especially important in sensitive areas like collars and waistbands. Breathable and moisture-wicking interlining helps regulate body temperature and prevent chafing.

Choosing the Right Interlining for Different Fabrics

Selecting the appropriate interlining for a given fabric type is crucial, as different materials require different levels of support, flexibility, and care.

1) Lightweight Fabrics

For delicate or lightweight fabrics like silk, satin, or chiffon, lightweight interlining is preferred to maintain the fabric’s natural drape without adding bulk. Fusible interlining with a soft adhesive can add subtle structure without damaging the fabric.

2) Medium-Weight Fabrics

Medium-weight fabrics like cotton, linen, or light wool can accommodate a slightly heavier interlining, such as woven or knit interlining, for added durability. Non-woven interlining is also suitable for specific areas like collars and cuffs requiring additional stiffness.

3) Heavyweight Fabrics

Heavy fabrics, including wool, denim, or canvas, can handle the weight and stiffness of thicker interlinings. Heavy woven or non-woven interlinings offer support without compromising the garment’s fit and help maintain the shape and structure of these fabrics.

4) Stretch and Knit Fabrics

Interlining with elastic or knit properties is ideal for stretchy or knit fabrics. This allows the garment to maintain flexibility and prevent sagging over time. Knit interlinings are common in activewear, sports bras, and leggings.

Interlining and Tailoring: Improving the Silhouette and Structure

In tailored garments, interlining is an essential component that significantly impacts the garment’s silhouette. It provides shape, enhances the shoulder line, and sharpens the lapel, ensuring the garment retains a structured, crisp appearance.

1) Creating a Sharp Silhouette

Interlining in the chest, lapels, and shoulders reinforces the fabric to create a sharp, well-defined silhouette. This is essential in suits, blazers, and coats, where a tailored look is synonymous with quality.

2) Adding Volume and Padding

Interlinings with additional padding often add volume to certain garment parts, like the shoulder area. By adding volume, interlining can create a powerful and polished appearance, enhancing the garment’s visual impact.

3) Adjusting Fit for Individual Body Types

Custom tailoring often involves adjusting interlining placement or thickness to accommodate an individual’s unique body shape. By carefully selecting the interlining and its application, tailors can create a garment that enhances the wearer’s physique while maintaining comfort.

Technological Advancements in Interlining Materials

With ongoing advancements in textile technology, interlining materials continue to evolve, offering more features and benefits.

1) Smart Interlining

Smart textiles, including sensor-integrated interlining, are beginning to emerge in the market. These interlinings can monitor the wearer’s body temperature and movements and even detect postural changes. They are particularly valuable in medical garments, sportswear, and wearable technology.

2) Eco-Friendly and Sustainable Interlining

Environmentally friendly interlining materials, such as recycled polyester and organic cotton, are now more accessible, catering to the demand for sustainable fashion. Biodegradable interlinings are designed to minimize environmental impact without compromising quality.

3) Nanotechnology for Enhanced Performance

Nanotechnology has introduced interlinings with advanced properties, such as water resistance and antibacterial and anti-odor functionalities. These interlinings are especially useful in sportswear, activewear, and medical garments.

Environmental and Sustainability Considerations in Interlining

As the textile industry increasingly emphasizes sustainability, interlining manufacturers focus on eco-friendly solutions.

1) Use of Recycled Materials

Many interlining manufacturers now incorporate recycled materials, reducing reliance on virgin resources. Recycled polyester is one of the most common materials used for sustainable interlining, providing the same quality and performance as new polyester with a smaller carbon footprint.

2) Biodegradable Interlining

Biodegradable interlining materials, such as organic cotton and natural fibers, are gaining popularity. These materials decompose more quickly than synthetic fibers, reducing their environmental impact once disposed of.

3) Reducing Waste and Emissions

The interlining production process is increasingly geared toward minimizing waste and emissions, with advancements in waterless dyeing, reduced chemical use, and energy-efficient production techniques.

Interlining is a fundamental component that greatly enhances garments’ performance, durability, fit, and comfort. With various interlining materials available, manufacturers and designers have various options to suit specific needs, from lightweight support to reinforced structure. Additionally, innovations in smart textiles and sustainable materials are paving the way for more advanced and eco-friendly interlining solutions. By carefully selecting and applying the right interlining, manufacturers can create garments that look and feel better and perform well over time, providing customers with high-quality, comfortable, and sustainable clothing.

Leave a Reply