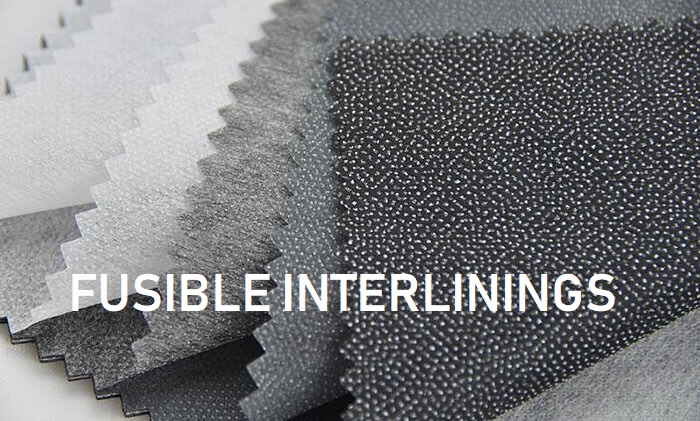

Fusible interlining manufacturing is a critical aspect of the textile and garment industry, and maintaining stringent quality standards is essential to ensure the production of reliable and high-quality interlining products. Various international and industry-specific standards and certifications play a pivotal role in guaranteeing the performance, safety, and consistency of fusible interlinings. In this article, we explore the significance of adhering to quality standards and obtaining certifications in the fusible interlining manufacturing process.

Adherence to Quality Standards

ISO Standards: ISO 9001 is an internationally recognized standard for quality management systems. Fusible interlining manufacturers that comply with ISO 9001 demonstrate their commitment to implementing effective quality management practices throughout their production processes. This standard ensures that the entire manufacturing process, from sourcing materials to final product inspection, is consistently monitored and optimized to meet customer requirements.

Oeko-Tex Standard 100: Oeko-Tex Standard 100 is a globally recognized certification that ensures textile products, including fusible interlinings, are free from harmful substances and safe for human use. Complying with this standard assures customers that the interlinings are free from hazardous chemicals and pose no risks to human health.

REACH Compliance: REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is a European Union regulation that addresses the safe use and handling of chemicals in products. Fusible interlining manufacturers that adhere to REACH compliance demonstrate their commitment to using safe and authorized substances in their interlining production.

ISO 14001: – Environmental Management System: ISO 14001 is a standard that focuses on environmental management systems. Manufacturers that adopt ISO 14001 demonstrate their dedication to minimizing their environmental impact and promoting sustainable practices.

Importance of Certifications

Product Performance Assurance: Certifications validate the performance and functionality of fusible interlinings, assuring customers that the products meet specific quality criteria. This enhances the credibility and reliability of the manufacturer and the product itself.

Global Market Access: Obtaining internationally recognized certifications allows Fusible Interlining Suppliers to access global markets with confidence. Customers and brands worldwide seek certified products, ensuring a broader customer base and increased market opportunities.

Compliance with Regulations: Certifications ensure that the fusible interlinings meet regional and international regulatory requirements, providing reassurance to customers and end-users that the products are safe and compliant.

Continuous Improvement: Working towards obtaining and maintaining certifications fosters a culture of continuous improvement within the manufacturing process. Manufacturers are continually motivated to enhance their product quality, sustainability, and customer satisfaction.

Quality standards and certifications are paramount in the fusible interlining manufacturing industry, guaranteeing that products are safe, reliable, and meet customer expectations. Complying with international standards and obtaining certifications demonstrates the commitment of manufacturers to providing high-quality, environmentally responsible, and sustainable fusible interlinings. As the industry evolves, adherence to these standards becomes increasingly critical, ensuring the ongoing advancement and trustworthiness of fusible interlining products in the global textile and garment market.

Leave a Reply