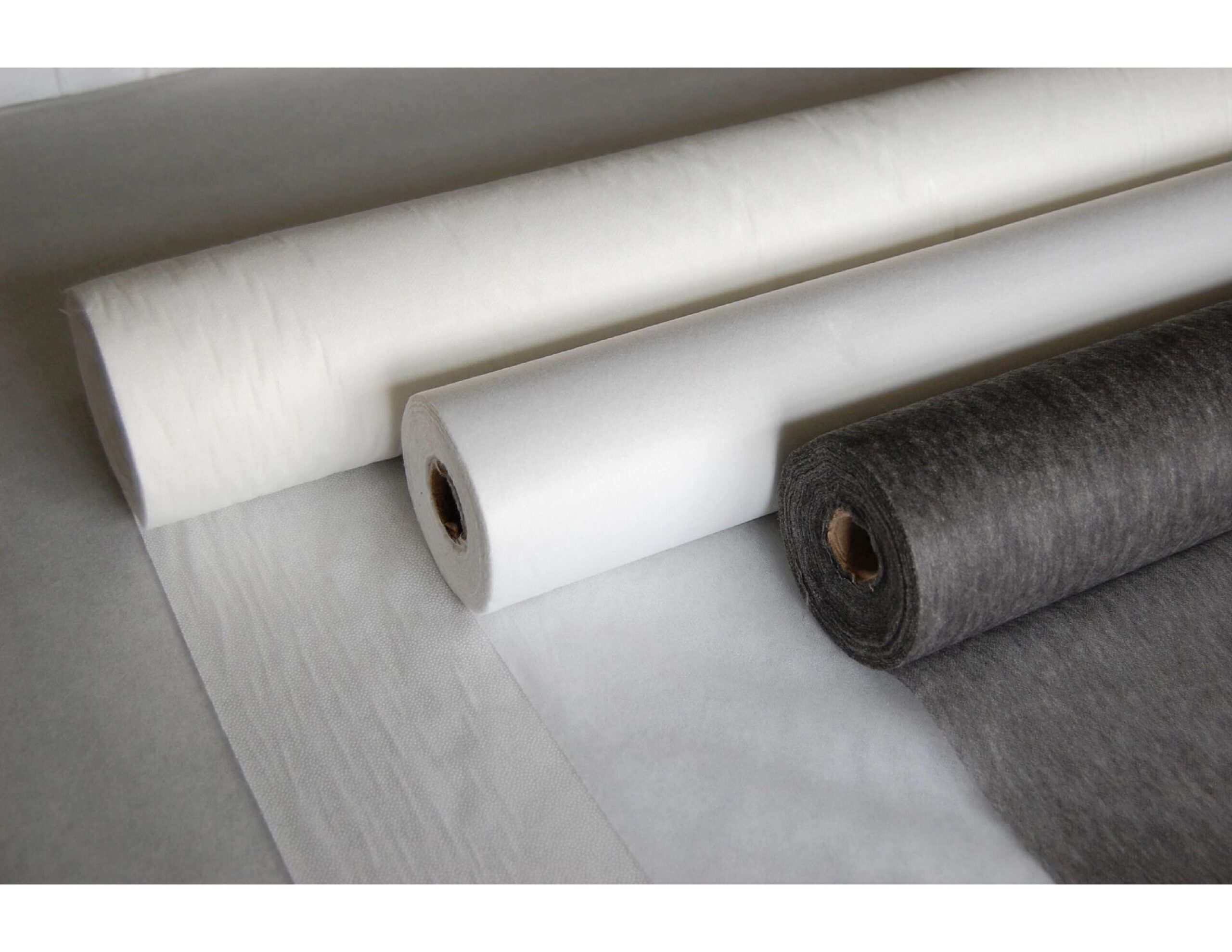

When it comes to garment manufacturing, choosing the right interlining is as essential as selecting the outer fabric. Interlining is vital in adding structure, durability, and a finished look to garments. Nonwoven interlining has become increasingly popular among various types of interlining materials due to its versatility, ease of application, and cost-effectiveness.

However, selecting the right one for your project can be challenging with a wide range of Non woven interlining fabrics. Understanding the properties, functions, and appropriate applications of non-woven interlining will help you make the best choice for your garment or project. This blog will cover non-woven interlining and its various types and provide a comprehensive guide to choosing the right Non woven interlining fabric for your project.

Non-woven interlining is a type of fabric made from fibers bonded together through various methods, such as mechanical, thermal, or chemical processes. Unlike woven interlining, which consists of interlaced threads, non-woven fabrics do not have a specific weave or knitting pattern. This makes them more cost-effective and easier to apply.

Interlining, in general, is used between the outer fabric and lining to provide support, shape, and strength to garments. It is commonly used in collars, cuffs, waistbands, and plackets to ensure the garment maintains its structure during use. Non woven interlining fabrics are particularly favored in the fashion industry for their affordability and versatility.

Types of Non-Woven Interlining

Different types of Non woven interlining fabrics offer distinct benefits depending on their construction and composition. Understanding these types will allow you to make an informed decision for your project.

1) Fusible Non-Woven Interlining

Fusible non-woven interlining has an adhesive coating on one side, allowing it to bond to the fabric when heat is applied. This makes attaching the interlining to fabric quick and easy, often requiring just a steam iron or heat press. Fusible interlining is commonly used in shirt collars, waistbands, and garment plackets.

Benefits:

- Easy to apply

- Provides a smooth and stable finish

- No sewing required

Best for:

- Structured garments like blazers and jackets

- Shirt collars and cuffs

- Dresses that require a polished finish

2) Sew-In Non-Woven Interlining

The sew-in non-woven interlining is not adhesive-backed, meaning it needs to be sewn into the garment. It is a preferred choice for delicate fabrics that may be damaged by heat or adhesives. Sew-in interlining offers more flexibility and is used when a softer, more natural drape is required.

Benefits:

- Suitable for delicate fabrics

- Allows for more control over the final appearance

- It can be used in garments requiring a soft drape

Best for:

- Lightweight fabrics like silk and chiffon

- Garments requiring a soft and natural look

- Projects where durability and flexibility are crucial

3) Water-soluble Non-Woven Interlining

Water-soluble, non-woven interlining is used in specialized applications where the interlining needs to dissolve after providing temporary support. For example, embroidery often uses it to stabilize the fabric during stitching. Once the embroidery is complete, the interlining is washed away, leaving only the embroidery intact.

Benefits:

- Provides temporary support for stitching or embroidery

- Dissolves after use, leaving no trace

- Perfect for delicate or intricate designs

Best for:

- Machine embroidery projects

- Delicate fabrics that require minimal interference

- Projects that need temporary stabilization

4) Double-Sided Fusible Non-Woven Interlining

Double-sided fusible non-woven interlining has adhesive on both sides. It is commonly used to bond two layers of fabric together. It can help craft projects, applique work, and certain home decor items requiring firm bonding between fabric layers.

Benefits:

- Bonds two fabrics together securely

- Helpful for crafting and applique

- Easy to apply with heat

Best for:

- Craft projects and DIY home decor

- Applique designs

- Projects requiring firm bonding between fabric layers

Key Factors to Consider When Selecting Non-Woven Interlining

Choosing the right non-woven interlining depends on several factors related to the garment’s characteristics, the outer fabric, and the desired finish. Below are the key factors you should consider to ensure your project comes out perfectly.

1) Fabric Type

The most crucial factor in choosing non-woven interlining is the type of fabric you are working with. For example, fusible interlining may not be suitable for heat-sensitive fabrics like silk or satin, as the heat required to bond the interlining may damage the fabric.

Tips:

- Lightweight fabrics: Use lightweight or soft, non-woven interlining to avoid bulkiness. Sew-in non-woven interlining is often a better option for delicate fabrics.

- Heavier fabrics: Thicker fabrics like wool or denim may require heavier interlining to provide adequate structure and support.

- Stretch fabrics: If you work with stretchy fabrics, consider using interlining with a bit of give or flexibility to match the fabric’s properties.

2) Adhesive vs. Sew-In

Choosing fusible (adhesive-backed) or sew-in non woven interlining depends mainly on the fabric and the project’s requirements.

Tips:

- Fusible interlining is best for projects where speed and convenience are important. It is ideal for structured garments like jackets and blazers.

- Sew-in interlining is ideal for delicate fabrics that could be damaged by heat or pressure. It is also useful when a more natural drape is needed in the garment.

3) Weight and Thickness

The weight and thickness of the interlining fabric should complement the weight of the outer fabric. A mismatched interlining can ruin a garment’s look and feel.

Tips:

- Lightweight interlining: Suitable for lightweight fabrics like chiffon, silk, or tulle.

- Medium-weight interlining: Works well with cotton, linens, and other medium-weight fabrics.

- Heavy-weight interlining: Best for outerwear fabrics like wool, denim, or heavy synthetics that require significant structure.

4) Drape and Flexibility

The interlining’s ability to drape and move with the fabric is essential for achieving the desired look of the garment. Stiff interlining will give a structured, rigid appearance, while softer interlining will provide a more natural drape.

Tips:

- For structured garments (e.g., suits and jackets), choose a stiff interlining that provides adequate support.

- For flowing garments (e.g., skirts, dresses), opt for softer, more flexible interlining to maintain the fabric’s natural movement.

5) Durability

Durability is another critical factor, especially for garments or projects subjected to frequent washing or heavy wear.

Tips:

- Choose non-woven interlining with high durability for garments that will experience heavy use or need frequent laundering.

- Ensure that the interlining is pre-shrunk or compatible with the fabric’s care instructions to avoid issues after washing.

6) Compatibility with the Outer Fabric

Before applying non-woven interlining, test it on a small piece of the outer fabric to ensure that the interlining bonds well together and doesn’t affect the fabric’s appearance.

Tips:

- For fusible interlining, ensure the adhesive bonds well without leaving residue on the fabric.

- For sew-in interlining, ensure the stitching doesn’t create visible puckering or lines on the fabric.

Steps to Applying Non-Woven Interlining

Once you’ve selected the appropriate non-woven interlining for your project, it’s essential to apply it correctly to achieve the desired results.

1. Pre-Washing

Pre-washing your fabric and interlining is essential to ensure that both materials shrink equally. This step helps prevent puckering or distortions after the garment has been washed.

2. Cutting the Interlining

Cut the interlining to match the shape and size of the pattern pieces you will reinforce. If using fusible interlining, cut slightly smaller than the outer fabric to avoid adhesive buildup on your iron.

3. Fusing (For Fusible Interlining)

- Place the interlining on the wrong side of the fabric, adhesive side down.

- Use a steam iron set to the appropriate heat level for your fabric. Apply even pressure for a few seconds, moving the iron continuously to avoid scorching the fabric.

- Allow the fabric to cool before moving to ensure the adhesive bonds properly.

4. Sewing (For Sew-In Interlining)

- Align the interlining with the wrong side of the fabric.

- Pin the interlining in place and sew it into the seam allowances to secure it.

- Press the fabric and interlining together after sewing to ensure a smooth finish.

Choosing a suitable Non woven interlining fabric ensures your garment or project has the proper structure, durability, and finish. Whether you’re working on a delicate dress, a structured blazer, or an intricate embroidery project, there is a non-woven interlining that will suit your needs.

You can select the best interlining that enhances the final product by considering factors such as fabric type, weight, flexibility, and durability. Additionally, understanding how to apply non-woven interlining correctly will ensure your project’s smooth and professional finish.

Leave a Reply